Crash-deformable battery systems

Today’s hybrid and electric vehicles use lithium-ion cells for the energy storage, which have a lower power density and thus need to be relatively large and heavy. Thus, electric vehicles are often heavier than the conventional ones.

Also, the energy storage is mostly positioned in those areas in vehicles, which are most unlikely to be deformed during a crash. These areas however are limited and therefore also limit the maximum battery capacity and the range of the vehicle.

Integrating batteries safely normally requires additional reinforcing of the vehicle and battery structure, which then again leads to an increased weight.

The key to develop lightweight vehicle and energy storage structures that meet the vehicle requirements is to include the energy storage and its components into an early phase of virtual development with the help of finite element methods. This however requires detailed knowledge and an appropriate numeric representation of the mechanical performance of the battery cells and modules.

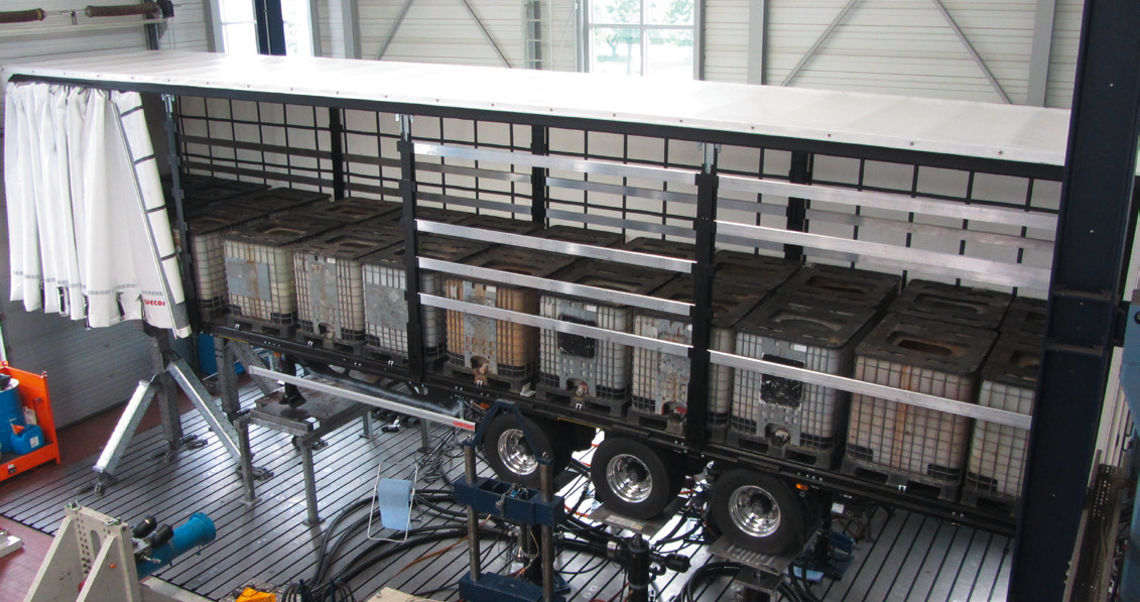

Within the publicly funded projects “e performance” (BMBF) and “OSTLER” (EU) such approaches where developed and implemented to design innovative battery systems.

In “e performance” a modular system was developed for electric vehicles. Key element is a modular and scalable battery system based on trapezoidal macro cells, which slip past each other while integrated deformation elements absorb the crash energy.

Within the EU-funded project OSTLER we developed a different approach and focused on how intelligent safety concepts like airbags for example can protect power storage systems. We therefore conducted various tests with three different cell types and also created a finite element model for a pouch cell, which represents the cell’s mechanical properties and thus helps us to evaluate the safety level in a crash.

fka World of Research

![[Foto: people working in the background with a abstract image of a process as overlay]](/images/artikel/MBSE/Model_Based_Systems_Engineering.png)

Model-Based Systems Engineering

Introduction and implementation of the Model-Based Systems Engineering (MBSE) approach

We move away from the traditional document-based approach and instead rely on interconnected digital models. A system model serves as a shared platform for communication between all teams involved in development. It acts as a central source of information, ensuring that crucial data is always up to date and accessible.

Read more ...

Strategy & Consulting |

Strategy Teaser

Exciting short studies on innovations and developments in the automotive industry by our experts from Strategy & Consulting.

Read more ...![[Foto: VW ID.3]](/images/artikel/bench/id3/vw-id3-IF2_2262.jpg)

Continuous Bechmarking

VW ID.3 Benchmarking

fka & FEV Consulting launched the comprehensive benchmarking program.

Read more ...

![[Foto: Crash-deformable Battery Systems]](/images/highlights/karosserie/crash-batteriesystem3.jpg)

![[Foto: Crash-deformable Battery Systems]](/images/highlights/karosserie/crash-batteriesystem4.jpg)

![[Foto: Daniel Wegener]](/images/personen/berger-lutz.jpg)