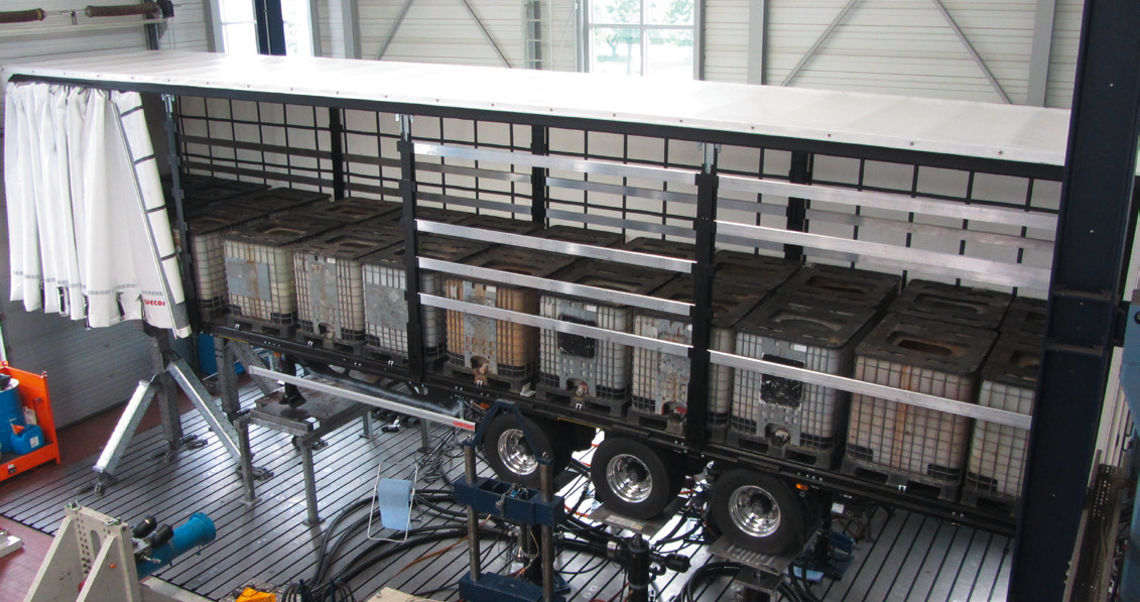

![[Photo: Material test]](/images/artikel/meterialmodelierung/materialmodelierung-1140x300.jpg)

Material modeling and characterization

The Finite Element Method (FEM) is an established tool in the development process of vehicle structures and components.

Simulations with implicit time integration allow, for example, the analysis of the stiffness and normal modes of vehicle bodies as well as different approaches to structural optimization, while explicit time integration is used for the evaluation of short-term dynamic load cases, such as crash situations.

The basis of every FEM-supported structural design process are validated modelling methods for depicting the materials and joining processes used.

Here fka offers the entire chain for the generation of validated material cards and joining technology models. The selection of the suitable simulation and modelling approach depends on the load or application. Based on the analysis of the boundary conditions of the system to be simulated, suitable material models, element types and interface models are selected.

Therefore, it is necessary to specify the model's properties, eg.:

- Metals

- Elastic or elasto-plastic behavior

- Anisotropy

- Triaxiality

- Synthetic materials

- Elastic or elasto-plastic behavior

- Visco-elastic behavior (foamed materials)

- Material failure

- Fibre-reinforced materials

- Orthotropy

- Failure modes (tension, compression, shear, delamination)

- Structure dissolution (crushing)

- Post-cracking behavior

- Joining technology

- Shear and tensile failure

- Mixed load and interaction

- Heat influence und thermal joining processes

The characterization of the materials or joints is carried out using a suitable test program, which is usually based on the relevant standards and guidelines, e.g. tests on coupon samples.

For the validation of the models, more complex tests, e.g. on generic components or profiles, are carried out, which can be carried out both quasistatically on the servo-hydraulic testbench and highly dynamically on the drop tower test rig.

fka offers the generation of material cards for a number of common FE solvers (e.g. LS-DYNA, Pam-Crash, Radioss, Nastran, Abaqus).

Ihr Ansprechpartner

Your contact

![[Foto: Daniel Wegener]](/images/personen/berger-lutz.jpg)

Dipl.-Ing. Lutz Berger

Head of Vehicle Concepts, Body & Interior

This email address is being protected from spambots. You need JavaScript enabled to view it.

Telefon: +49 241 8861 128

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 241 8861 128

fka World of Research

![[Foto: people working in the background with a abstract image of a process as overlay]](/images/artikel/MBSE/Model_Based_Systems_Engineering.png)

Model-Based Systems Engineering

Introduction and implementation of the Model-Based Systems Engineering (MBSE) approach

We move away from the traditional document-based approach and instead rely on interconnected digital models. A system model serves as a shared platform for communication between all teams involved in development. It acts as a central source of information, ensuring that crucial data is always up to date and accessible.

Read more ...

Strategy & Consulting |

Strategy Teaser

Exciting short studies on innovations and developments in the automotive industry by our experts from Strategy & Consulting.

Read more ...![[Foto: VW ID.3]](/images/artikel/bench/id3/vw-id3-IF2_2262.jpg)

Continuous Bechmarking

VW ID.3 Benchmarking

fka & FEV Consulting launched the comprehensive benchmarking program.

Read more ...

![[Foto: Material-Test]](/images/artikel/meterialmodelierung/materialmodelierung-1.jpg)

![[Foto: Material-Test-Simulation]](/images/artikel/meterialmodelierung/materialmodelierung-2.jpg)