Development of Battery Systems

The high-voltage battery at the center of attention

The high-voltage battery is currently the focus of attention in the development processes of battery electric vehicles due to its high share of value added to the overall vehicle as well as its high technical potential. In addition to cell development, which takes place isolated from the vehicle, the focus is on E/E architecture, the improvement of mechanical properties of the system and thermal cell conditioning.

While current battery electric passenger cars are still characterized by so-called conversion design (derivation of variants) due to the use of derivatives of combustion engine vehicles, current developments are resulting in dedicated vehicles with a purpose design (redesign of the vehicle structure). This is accompanied by an increase in the number of units and a greater variety of models. This paradigm shift leads to fundamentally changed boundary conditions, including vehicle integration, geometric design, scalability and performance of battery systems.

Projected charging capacities of up to 350 kW and beyond lead to very large heat input into the cell. In order to be able to control cell degradation, the demands on heat dissipation and on the most homogeneous temperature distribution possible at cell and system level are growing. This can only be guaranteed by effective thermal management.

The development of efficient and cost-effective solutions therefore requires a comprehensive understanding of the entire vehicle, the possible operating conditions and the resulting energetic and mechanical requirements as well as the legal framework for the certification of battery systems.

Development expertise through an interdisciplinary and agile process

In recent years, fka has acquired broad expertise in the definition, design, prototyping and commissioning of battery modules and systems and can contribute to efficient development with established processes.

This process starts with a prioritization of the relevant requirements, e.g. from norms and standards and from (typical) OEM requirements. On this basis, a specific concept is defined and the development goals defined.

The system development is then carried out together with the customer in an interdisciplinary, agile process covering modularisation and structural design, E/E architecture and thermal management. fka has comprehensive and in-depth technological expertise in the relevant areas of battery system development. The development expertise is complemented by engineering services as project management, strategy development and market analyses, thus completing the portfolio.

Specialists from the Strategy and Consulting, Body, Powertrain, Electrics/Electronics, Acoustics and Thermal Management divisions work hand in hand. The latest software tools are used for efficient system design.

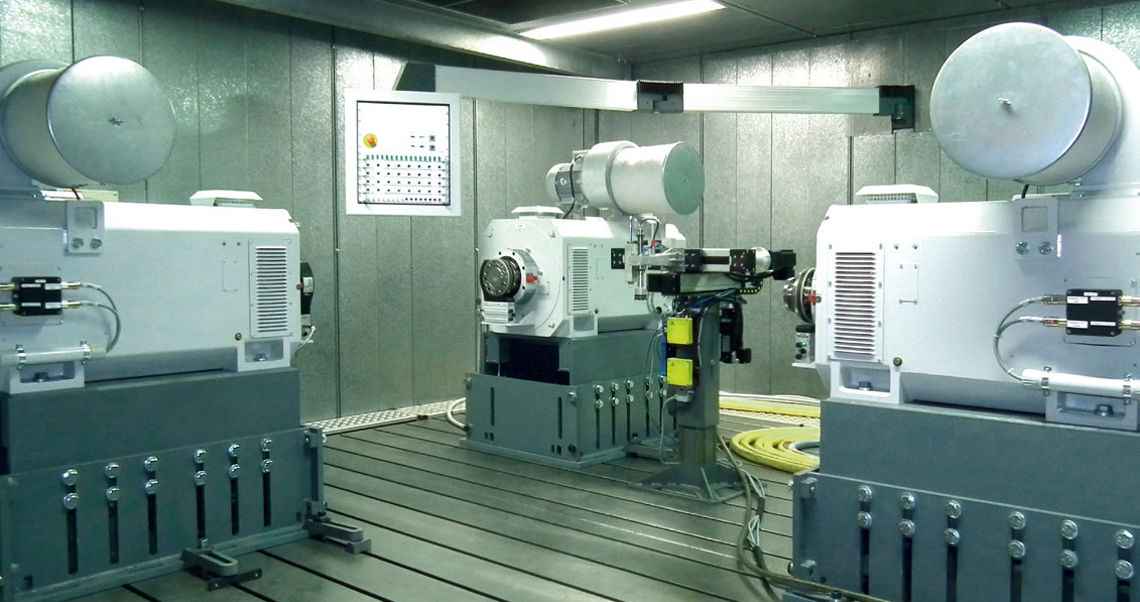

The corresponding standard and special test benches are also available to fka for validation and validation of concepts. These include a servo-hydraulic test centre (static tests), a crash system (dynamic tests), a battery test system and a thermal laboratory (E/E and thermal management).

Ihre Ansprechpartner

Your contact

![[Foto: Michael Funcke]](/images/personen/funcke-michael.jpg)

Dr.-Ing. Michael Funcke

Senior Engineer Battery Systems

This email address is being protected from spambots. You need JavaScript enabled to view it.

Telefon: +49 241 8861 132

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 241 8861 132

![[Foto: Oliver Voßen]](/images/personen/vossen-oliver.jpg)

Oliver Voßen M.Sc.

Head of Powertrain & Electrical Systems

This email address is being protected from spambots. You need JavaScript enabled to view it.

Telefon: +49 241 8861 214

This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 241 8861 214

fka World of Research

![[Foto: people working in the background with a abstract image of a process as overlay]](/images/artikel/MBSE/Model_Based_Systems_Engineering.png)

Model-Based Systems Engineering

Introduction and implementation of the Model-Based Systems Engineering (MBSE) approach

We move away from the traditional document-based approach and instead rely on interconnected digital models. A system model serves as a shared platform for communication between all teams involved in development. It acts as a central source of information, ensuring that crucial data is always up to date and accessible.

Read more ...

Strategy & Consulting |

Strategy Teaser

Exciting short studies on innovations and developments in the automotive industry by our experts from Strategy & Consulting.

Read more ...![[Foto: VW ID.3]](/images/artikel/bench/id3/vw-id3-IF2_2262.jpg)

Continuous Bechmarking

VW ID.3 Benchmarking

fka & FEV Consulting launched the comprehensive benchmarking program.

Read more ...

![[Foto: Slave Board]](/images/artikel/batteriesystementwicklung/batteriesystementwicklung800x600.jpg)

![[Foto: Battery System Test]](/images/artikel/batteriesystementwicklung/batteriesystementwicklung800x6002.jpg)